| NASA

is building an advanced humanoid system called Robonaut, currently

under development at the Johnson Space Centre.

by Chris

Culbert

The Shape

of Things to Come

Over the past

five decades, space flight hardware has been designed for human

servicing. Space walks are planned for most of the assembly missions

for the International Space Station, and they are a key contingency

for resolving on-orbit failures. Combined with substantial investment

in EVA tools, this accumulation of equipment requiring a humanoid

shape and an assumed level of human performance presents a unique

opportunity for a humanoid system.

While the depth

and breadth of human performance is beyond the current state of

the art in robotics, NASA targeted the reduced dexterity and performance

of a suited astronaut as Robonaut's design goals, specifically using

the work envelope, ranges of motion, strength and endurance capabilities

of space walking humans. This article describes the design effort

for the Robonaut system.

Mechanism

Design

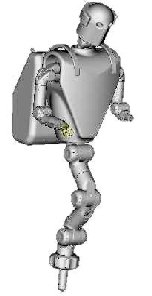

The manipulator

and dexterous hand have been developed with a substantial investment

in mechatronics design. The arm structure has embedded avionics

elements within each link, reducing cabling and noise contamination.

Unlike some systems, Robonaut uses a chordate approach to data management,

bringing all feedback to a central nervous system, where even low-level

servo control is performed. This biologically inspired neurological

approach is extended to left-right computational symmetry, sensor

and power duality and kinematical redundancy, enabling learning

and optimization in mechanical, electrical and software forms. The

theory that manufacturing tools caused humans to evolve by requiring

skills that could be naturally selected is applied to Robonaut's

design as well. The set of EVA tools used by astronauts was the

initial design consideration for the system, hence the development

of Robonaut's dexterous five-fingered hand and human-scale arm that

exceeds the range of motion of even unsuited astronauts. Packaging

requirements for the entire system were derived from the geometry

of EVA access corridors, such as pathways on the Space Station and

airlocks built for humans.

NASA

Is

this the future of robotics...?

|

Sensors and

Telepresence Control

Robonaut's broad mix of sensors includes thermal, position, tactile,

force and torque instrumentation, with over 150 sensors per arm.

The control system for Robonaut includes an onboard, real time CPU

with miniature data acquisition and power management in a small,

environmentally hardened body. Off-board guidance is delivered with

human supervision using a telepresence control station with human

tracking.

Meeting the needs

To meet the dexterous manipulation needs foreseen in future NASA

missions, the Automation, Robotics, and Simulation Division at Johnson

Space Center is developing Robonaut, a highly dexterous anthropomorphic

robotic system. Robonaut is advancing the state of the art in anthropomorphic

robotic systems, multiple use tool handling end effectors, modular

robotic systems components and telepresence control systems. The

project has adopted the design concept of an anthropomorphic robot

the size of an astronaut in a space suit and configured with two

arms, two five-fingered hands, a head and a torso. Its dexterous

pair of arms enables dual-arm operations and its hands can interface

directly with a wide range of interfaces without special tooling.

Its anthropomorphic design enables intuitive telepresence control

by a human operator.

Head

Robonaut's head is still a work in progress, but the existing system

includes an articulated neck that allows the teleoperator to point

Robonaut's face. The head holds two small color cameras that deliver

stereo vision to the operator's helmet display, yielding a form of

depth perception. The interocular spacing of the cameras is matched

to typical human eye spacing, with a fix vergence at arm's reach.

The neck drives are commanded using a 6 axis Polhemus sensor mounted

on the

NASA

NASA

The

operator can see through two cameras in Robonauts' head

|

teleoperator's

helmet, and can track the velocities of typical human neck motions.

Like the arms, the neck's endoskeleton is covered in a

fabric skin, which is fitted into and under the helmet. The helmeted

approach is unusual in the robotics world, where cameras are typically

mounted in exposed locations on pan-tilt-verge units. Robonaut's

requirements for a rugged design, working with astronauts in cluttered

environments drove the design towards a better protection system,

such as

the helmets that humans where here on Earth. The helmet is

made of an epoxy

resin, "grown" using a stereo lithography machine at the Johnson space

center. As you can see, the design was inspired by Centurian armor,

giving Robonaut some attitude. The neck joints are similar

to the joints and

are controlled with the same real-time control system. Their kinematics

is based on a pan-tilt serial chain, with the first rotation about

Robonaut's spine, and then a pitch motion about a lateral axis. The

pitch motion axis does not pass through the camera sensors, but is

instead 3 inches below, like the Atlas joint in the human neck. This

offset (actually a D-H link length) allows the cameras to translate

forward, letting Robonaut see down over its chest.

Hand

NASA

The

Robonaut hand replicates the size and capability of an astronauts

hand

|

Many ground breaking dexterous robot hands have been developed over

the past two decades. These devices make it possible for a robot

manipulator to grasp and manipulate objects that are not designed

to be robotically compatible. While several grippers have been designed

for space use and some even tested in space, no dexterous robotic

hand has been flown in EVA conditions. The Robonaut Hand is one

of the first under development for space EVA use and the closest

in size and capability to a suited astronaut’s hand. Robonaut Hand

will be able to fit into all the required places. Joint travel for

the wrist pitch and yaw is designed to meet or exceed the human

hand in a pressurized glove. The hand and wrist parts are sized

to reproduce the necessary strength to meet maximum EVA crew requirements.

EVA space compatibility separates the Robonaut Hand from many others.

All component materials meet outgassing restrictions to prevent

contamination that could interfere with other space systems. Parts

made of different materials are toleranced to perform acceptably

under the extreme temperature variations experienced in EVA conditions.

Brushless motors are used to ensure long life in a vacuum. All parts

are designed to use proven space lubricants. The Robonaut Hand has

a total of fourteen degrees of freedom. It consists of a forearm

which houses the motors and drive electronics, a two degree of freedom

wrist, and a five finger, twelve degree of freedom hand. The forearm,

which measures four inches in diameter at its base and is approximately

eight inches long, houses all fourteen motors, 12 separate circuit

boards, and all of the wiring for the hand. The hand itself is broken

down into two sections : a dexterous work set which is used for

manipulation, and a grasping set which allows the hand to maintain

a stable grasp while manipulating or actuating a given object. This

is an essential feature for tool use. The dexterous set consists

of two three degree of freedom fingers (pointer and index) and a

three degree of freedom opposable thumb. The grasping set consists

of two, one degree of freedom fingers (ring and pinkie) and a palm

degree of freedom. All of the fingers are shock mounted into the

palm.

NASA

The

range of motion in the arm exceeds that of a human

|

Arms

Robonaut's arms

are human scale manipulators designed to fit within the exterior

volume of an Astronaut's suit (the EMU). Beyond its volume, design

objectives were human equivalent strength, human scale reach, thermal

endurance to match an 8 hour EVA, fine motion, high bandwidth dynamic

response, redundancy, safety, and a range of motion that exceeds

that of a human limb. The arm has a dense packaging of joints and

avionics developed with the mechatronics philosophy. The endoskeletal

design of the arm houses thermal vacuum rated motors, harmonic drives,

fail-safe brakes and 16 sensors in each joint (saves on the health

insurance quotes!). Custom lubricants, strain gages, encoders

and absolute angular position sensors were developed in house to

make the dense packaging possible. The Roll-Pitch-Roll-Pitch-Roll-Pitch-Yaw

kinematic tree is covered in a series of synthetic fabric layers,

forming a skin that provides protection from contact and extreme

thermal variations in the environment of space. Two of these arm

joints have already been tested in a thermal vacuum chamber at JSC,

where they performed well as the temperature was varied from -25C

to 105C.

Robonaut

Control System

The Robonaut control system architecture must respond to several

interesting challenges. It must provide safe, reliable control for

47+ degrees of freedom. It must be controllable via direct teleoperation,

shared control, and full autonomy. It must maintain performance

in a harsh thermal environment. It must execute at the required

rate on reasonable computing hardware. These challenges cannot be

met by using only classical robot control methods. Advanced control

theory in the areas of grasping, force control, intelligent control,

and shared control must be developed to the point where the control

is suitable for critical applications to fully realize the capability

of the Robonaut. The overall control

architecture is being developed around the concept of creating sub-autonomies

which are used to build the main system. These autonomies each combine

controllers, safety systems, low-level intelligence, and sequencing.

As a result, each is a self contained, peer system which interacts

with the other peers.

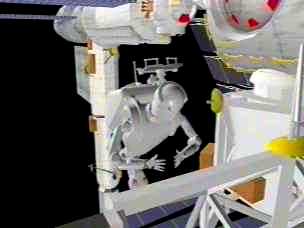

NASA

Space

walks will be the work of robots

|

An example

of the force controller sub-autonomy is shown below. The force safety

system is an integral part of the sub-autonomy. Its limits are controlled

by the force sequencer which configures the sub-autonomy for the

selected force mode. When the safety system detects a problem, an

input reaches a design criteria, or a mode change occurs the force

sequencer handles an orderly configuration change of the force control

sub-autonomy. The mode of the joint control system required to implement

the force mode is decided by the force sequencer and is sent to

the joint control sub-autonomy. System sub-autonomies include task

sequences, Cartesian control, vision, teleoperator interface, joint

control, and grasping among others. Higher level sub-autonomies

make decisions as to what services the lower level sub-autonomies

need to provide

to implement the required tasks. The overall system design makes

conflicts in requests for services either impossible or allows for

arbitration by system level autonomies.

Each sub-autonomy

handles its own internal safety and decision making. If a failure

occurs, a lower level sub-autonomy can request a shutdown or reconfiguration

from a higher level sub-autonomy or the main system controller which

will handle the system level actions required. The advantages of

this approach are each sub-autonomy can be tested individually and

the object orientedness of the system is enhanced. Computing environment

The computing environment chosen for the Robonaut project includes

several state-of-the-art technologies.

The PowerPC

processor was chosen as the real-time computing platform for its

performance and its continued development for space applications.

The computers and their required I/O are connected via a VME backplane.

The processors run the VxWorks real-time operating system. This

combination of flexible computing hardware and operating system

supports varied development activities. The software for Robonaut

is written in C and C++. ControlShell, a software development environment

for object oriented, real-time software development, is used extensively

to aid in the development process. ControlShell provides a graphical

development environment which enhances the understanding of the

system and code reusability.

|